The History of Knife Manufacturing

The knife is one of the oldest tools used by mankind. Initially made from obsidian and flint during the Stone Age, cutting tools gradually evolved into their modern form with the discovery of bronze, iron, and steel. Knives are not only kitchen tools but also play an important role in warfare, hunting, and craftsmanship.

Knife Use from Ancient Times to the Present

In the Stone Age, knives were the most important tools for survival. Primitive knives used for cutting meat, skinning animals, and building shelters played a significant role in humanity’s journey toward civilization.

The Art of Knife Making in the Ottoman Empire

During the Ottoman period, knife making was valued everywhere, from the palace to the marketplace. Centers such as Bursa, Sürmene, and Yatağan were renowned for their craftsmanship and skill. Handmade knives were not only considered cutting tools but also works of art.

The Development of the Knife Industry Today

With the Industrial Revolution, knife manufacturing moved to the assembly line. CNC machines, laser cutting, and new alloys made knives more durable and affordable. Today, there is a wide range of knives available, from kitchen knives to military tactical knives.

Materials Used in Knife Manufacturing

The most important factor determining knife quality is the material used. The type of steel directly affects the sharpness, durability, and rust resistance of the knife.

Carbon Steel and Stainless Steel

- Carbon steel knives are sharper, but can rust easily when exposed to moisture.

- Stainless steel, on the other hand, is more resistant to rust, but some types may not be as sharp as carbon steel.

Iron, Nickel, and Other Alloys

Different alloys are used in knife production to increase the strength of steel. Nickel, chromium, and vanadium increase durability and extend the life of the knife.

Wood and Composite Materials Used for Handles

The handle of a knife is very important for comfort of use. While walnut and rosewood are preferred in traditional knives, carbon fiber and polymer composites are used in modern knives.

Traditional Methods in Knife Manufacturing

Knife making has been carried out for centuries using special techniques passed down from master to apprentice. Although traditional methods are far removed from modern technology, they are works of art created through a combination of manual labor and patience.

Forging Technique

One of the most well-known methods is the forging technique. Steel is heated to a high temperature and shaped by hammering on an anvil. This process increases both the durability and aesthetic value of the knife.

Handmade Knife Production

Handmade knives, which are crafted by the master at every stage, can be produced specifically for each individual. Every detail, from the handle to the sheath, is a reflection of craftsmanship and artistic touch.

Master-Apprentice Relationship and Craftsmanship

In traditional knife making, knowledge is not gained from books but from the experience of masters. Apprentices spend years working in the workshop to become true knife masters. This process highlights the importance of craftsmanship and patience.

Modern Knife Manufacturing Techniques

With the industrial revolution and technological advancements, significant innovations have emerged in knife manufacturing.

Knife Making with CNC Technology

Computer-controlled CNC machines can produce knives with high precision. This method offers significant advantages in mass production.

Laser Cutting and Heat Treatment Methods

Laser technology enables steel to be cut with millimeter precision. The heat treatment that follows determines the hardness and durability of the knife.

Differences Between Mass Production and Handcrafting

- Mass production: More affordable and faster.

- Handcrafting: More personal, aesthetic, and collectible.

Knife Production Process Step by Step

The production process of a knife is more complex than one might think. Here are the basic steps:

Design and Drawing Stage

Each knife is first drawn on paper or a computer screen. The design is determined according to its intended use.

Shaping the Steel

Raw steel sheet is prepared in the desired shape using cutting and forging methods.

Heat Treatment and Hardening

The steel is hardened by heating and cooling it at specific temperatures. This stage is the most critical point in determining the quality of the knife.

Sharpening and Finishing

The knife is sharpened with special stones to increase its sharpness. Then the handle is attached and the surface is polished.

Types of Knives and Their Uses

Not all knives are the same. They vary depending on their intended use.

Kitchen Knives

Chef’s knives, slicing knives, filleting knives, and bread knives are the most commonly used types in the kitchen.

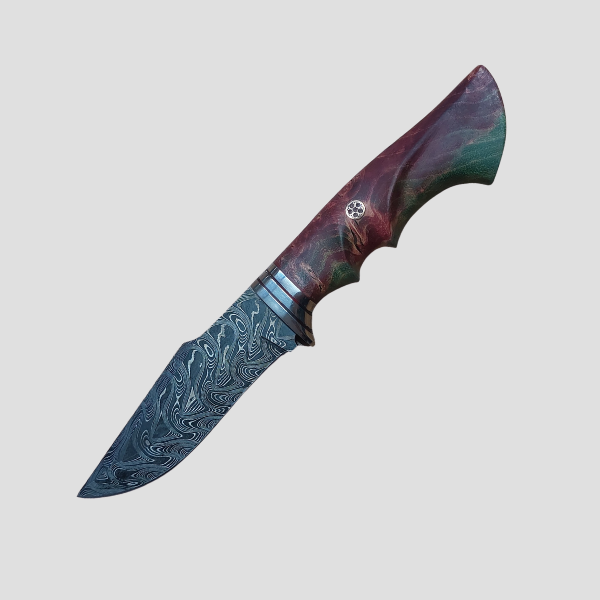

Hunting and Camping Knives

Durability and versatility are the main priorities. They are typically made from thick steel.

Industrial and Military Knives

These are professional knives used for cutting, carving, or defense. Military knives undergo special durability tests.

Knife Manufacturing in Turkey

Turkey is a country known for centuries for its knife manufacturing and ironwork. This art, which dates back to the Ottoman Empire, has developed in different cities with their own unique styles. However, Denizli Yatağan knives hold a special place due to their historical origins and tradition of craftsmanship.

Denizli Yatağan Knives

Denizli’s Yatağan district has made a name for itself around the world with its knife craftsmanship. Yatağan knives are known for their sharpness, durability, and aesthetic curved design. The origins of these knives date back to the Ottoman period. According to historical sources, Yatağan masters produced not only knives for kitchen and daily use but also durable swords and knives that could be used on the battlefield.

One of the most striking features of Yatağan knives is their handle design. Handles, typically made from horn, bone, or wood, add both aesthetic and ergonomic value to the knife. In addition, the knives feature the marks of the craftsmen, carved patterns, and traditional motifs. This elevates them from ordinary cutting tools to works of art.

Today, knife-making in Yatağan is still done by hand. Masters shape the iron by hammering it over a hot fire and stamp their signature on each knife. This tradition has been recognized by UNESCO as worthy of study under the “Intangible Cultural Heritage” category. Yatağan knives are not only popular in Turkey but are also sought after by collectors and professional users abroad.

Sürmene Knives

The Sürmene district of Trabzon is the most famous knife production center on the Black Sea. Sürmene knives are renowned for their sharpness and durability. Known primarily for kitchen knives, Sürmene plays an important role in Turkey’s knife exports.

Bursa Knives

Bursa has been known for its knife-making since the Ottoman period. Bursa knives are particularly preferred for daily use and in the kitchen. The city’s master craftsmen combine modern techniques with traditional craftsmanship in their production.

World-Famous Knife Centers

Knife manufacturing has a long-standing tradition in different parts of the world. Each country and region has its own unique knife-making techniques, materials, and aesthetic sense.

Japan – Katana and Samurai Knives

Katanas, crafted by Japanese masters, are renowned for their sharpness and durability. These knives, a symbol of samurai culture, are still considered among the finest examples of steelwork in the world.

Germany – Solingen Knives

The city of Solingen in Germany is one of the world’s most renowned centers for kitchen knives. Solingen knives, which achieve high quality in mass production, are frequently preferred by professional chefs.

USA – Modern Hunting Knives

America stands out for its modern knives designed for hunting and camping. Various brands also offer special edition knives with collectible value.

Turkey – Denizli Yatağan Knives

Turkey holds a special place in the world for its knife-making tradition. In particular, the Yatağan district of Denizli has been renowned for its knife craftsmanship throughout history. Yatağan knives are both functional and aesthetically pleasing. Known for their curved shape and sturdy steel, these knives were used on battlefields during the Ottoman period. Today, they are not only coveted by collectors but also preferred for everyday use.

Safety and Quality Standards in Knife Manufacturing

Knife production is not just about sharpness and aesthetics. Safety and quality are also the most critical elements in this process. The modern knife industry must produce in accordance with both national and international standards.

ISO and International Certifications

Many manufacturers around the world have quality management certifications such as ISO 9001 to certify the quality of their products. In addition, the approval of alloys used in stainless steel knives for food safety is also very important.

Occupational Health and Safety Measures

Knife makers work with high temperatures, sharp surfaces, and heavy machinery. Therefore, the use of personal protective equipment (gloves, goggles, earplugs) is mandatory. In addition, regular ventilation and fire safety measures must be taken in workshops.

Handmade Knives or Factory Production?

One of the most frequently asked questions when purchasing a knife is whether to choose handmade or mass-produced.

Advantages and Disadvantages

Handmade Knives:

- Each one is unique and has collectible value.

- They have sharper and more aesthetic craftsmanship.

- However, they are more expensive and take longer to produce.

Factory-Made Knives:

- They are more economical and easily accessible.

- Thanks to mass production, thousands of knives of the same quality can be produced.

- However, they do not have the same artistic value as handmade knives.

Collector’s Value and Aesthetic Elements

A knife is not just a tool, but also a work of art. Handmade Yatağan or Japanese knives, in particular, are highly valued by collectors.

Knife Care and Usage Recommendations

Even the highest quality knife will not last long without proper care.

Proper Sharpening Techniques

Knives should be sharpened regularly with special sharpening stones or professional sharpening devices. Improper sharpening shortens the life of the knife.

Protection Against Rust

Carbon steel knives should be oiled regularly.

- Even stainless steel knives can become stained if left in moisture for long periods of time.

The Future of Knife Manufacturing

Technology and new material research are also shaping knife manufacturing.

Nanotechnology and New Materials

In recent years, nano-coating technology has been used on knife surfaces to increase resistance to rust and wear. Ceramic and titanium alloy knives have also become popular.

Environmentally Friendly Production Methods

The use of recyclable materials and energy-efficient production techniques are increasingly being adopted in knife manufacturing. This helps protect nature and ensures sustainability.

Knife Manufacturing from Tradition to the Future

Knife manufacturing is an art as old as humanity itself and has deep cultural roots. In Turkey, centers such as Denizli Yatağan, Sürmene, and Bursa keep this tradition alive, while countries like Japan, Germany, and the United States also share their own knife cultures with the world.

Today, a knife is not merely a cutting tool but also a cultural heritage, a symbol of craftsmanship, and a product that reflects the pinnacle of technological advancement.

Frequently Asked Questions About Knife Manufacturing

Türkiye’den Dünyaya Kaliteli Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları imal eden firma.

Palta Outdoor, doğaya saygılı ve yeniliğe açık bir ekip tarafından tasarım ve tutkunun birleşimiyle doğdu. 1997’de Denizli’nin Serinhisar İlçesi Yatağan Mahallesi’nde başlayan geleneksel bıçakçılık serüvenimizi, 2020’de modern üretim teknikleriyle buluşturarak Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları ve kamp malzemeleri imalatı alanında dünya çapında bir marka haline geldik.

Türkiye’den Dünyaya Kaliteli Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları imal eden firma.

Palta Outdoor, doğaya saygılı ve yeniliğe açık bir ekip tarafından tasarım ve tutkunun birleşimiyle doğdu. 1997’de Denizli’nin Serinhisar İlçesi Yatağan Mahallesi’nde başlayan geleneksel bıçakçılık serüvenimizi, 2020’de modern üretim teknikleriyle buluşturarak Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları ve kamp malzemeleri imalatı alanında dünya çapında bir marka haline geldik.