One of the most critical pieces of equipment you should bring with you when camping is undoubtedly a camping knife. Both in terms of safety and functionality, a properly manufactured knife can be a lifesaver in the wilderness. In this article, we will take a detailed look at every step of camp knife manufacturing. If you want to make your own knife or aim to become an expert in this field, this guide is for you!

This article may interest you. How Are Knives Made? (Step-by-Step Guide from the Masters)

What is a Camping Knife and Why is it Important?

Basic Features of a Camping Knife

A camping knife is a special knife designed to perform many functions such as survival in nature, food preparation, wood cutting, and shelter construction. The most important criteria in the production of these knives are durability, versatility, and ergonomics. A typical camping knife usually has a blade length ranging from 10 to 20 cm. The handle is designed to be sturdy, non-slip, and comfortable to grip. The weight balance must be perfect to allow the user to use the knife comfortably for extended periods.

During the manufacturing process, the camping knife must be designed to handle both rough tasks and precise cuts with sufficient control. This is achieved through the right choice of steel, proper shaping, and suitable handle material.

Uses and Advantages

Don’t underestimate the camping knife. This small but effective tool makes life easier in many ways, from cutting rope to cleaning fish, splitting wood to opening cans. Here are the main uses:

- Cutting tree branches and splitting wood

- Building shelters

- Cutting and preparing food

- Ensuring personal safety (in the wild)

- Camping tasks such as cutting rope and untangling knots

Combining so many functions in a single tool lightens the load for campers and makes them feel more confident in nature. For this reason, making your own knife instead of buying a ready-made one from the market is both more economical and offers a more personalized experience.

Types of Camping Knives

Fixed Blade Camping Knives

Fixed blade models are the most common and reliable camping knives. The blade extends into the handle, which increases durability. Thanks to this structure, known as a full tang, the knife cannot break at the handle. Fixed blade knives are ideal for heavy-duty use in harsh outdoor conditions. They offer superior performance in tough tasks such as cutting wood, splitting logs, and skinning animals.

In terms of manufacturing, fixed blade models are easier to produce because they do not contain complex structures such as folding mechanisms. They also offer advantages in terms of cleaning and maintenance because they do not have parts that can trap dirt, such as hinges or spring mechanisms.

Foldable Camping Knives

Foldable knives are preferred by lightweight campers and minimalists. They are easy to carry and can be safely stored in a pocket or bag. However, they are less durable than fixed-blade knives. Producing foldable knives requires more technical knowledge and equipment for someone looking to manufacture camping knives.

Key considerations in production include strong hinge systems, locking mechanisms, and a secure grip. EDC (Everyday Carry) style knives typically fall into this category.

Special-Purpose Knives

These knives are designed for more specialized uses, such as hunting knives, bushcraft knives, or military knives. For example, a bushcraft knife may have a special spine design to be compatible with a fire-starting rod. When starting production of a camping knife, such specialized designs can also be considered depending on the intended use. Although their production is more complex, focusing on specialized knives can be profitable if you aim to target a niche market.

Introduction to Camping Knife Manufacturing

Selecting the Right Materials

The right materials are the foundation of any job. The first decision to be made in camping knife production is the main material to be used. Steel types play a major role here. However, it is not just steel that is important; the material used for the handle is just as important. Here are the basic materials used in camping knife production:

- Types of Steel: Carbon steel (1095), stainless steel (440C, AUS-8), D2, VG-10, etc.

- Handle Materials: Wood, G10, Micarta, rubber, leather, bone

- Other Materials: Brass pins, epoxy adhesive, protective varnishes

If your goal is lightness, you should choose different materials than if your goal is durability. For example, stainless steel requires less maintenance, while carbon steel is easier to sharpen and becomes sharper.

Tool and Equipment List

Camp knife manufacturing is a task that requires serious equipment. Here are some basic tools you will need to get started:

- Band saw or hand saw

- Grinding machine (belt grinder)

- Drill and various bits

- Stove or oven for heat treatment

- Hardening oil

- Vices, adhesives, and pins for handle assembly

- Polishing machine (for final polishing)

- Sharpening stone or systems

If you are an amateur, you can make some of these tools by hand, but if you want to become a professional over time, high-quality equipment is essential.

Steel Selection and Heat Treatment Process

Which Steels Are Used?

The choice of steel directly affects the performance of the knife. An ideal camping knife should be very hard but not brittle. The most commonly used types of steel are:

- 1095 Carbon Steel: Affordable, easy to shape, but susceptible to rust.

- D2 Steel: Semi-stainless, high wear resistance, hard.

- 440C Stainless Steel: Good balance of hardness and rust resistance.

- AUS-8: Japanese-made, affordable, and easy to work with.

- S30V: High quality, expensive but long-lasting and resistant to wear.

When choosing steel, you should balance the intended use and your budget.

Hardening and Tempering Processes

One of the most critical aspects of manufacturing is ensuring that the steel undergoes the correct heat treatment. This process determines how sharp the blade will remain and how resistant it will be to impact.

- Hardening: The steel is heated to a specific temperature (typically 800-900°C), then rapidly cooled in oil.

- Tempering: The hardened steel is held in an oven at a lower temperature (180-220°C) for several hours. This process reduces the brittleness of the steel.

Improper heat treatment can cause the blade to crack or break completely. Therefore, patience, knowledge, and the right equipment are essential at this stage.

Knife Shaping and Grinding Techniques

Shaping Stages

The rough draft of a camping knife is typically taken from a steel plate. Using a band saw, plasma cutter, or grinding machines, the knife’s rough outer form is created. For example, you can enhance durability by forming unevenly curved edges or a “full tang” structure in fixed knives.

You can follow these steps during the shaping process:

- Drawing and Mold Removal: It is very useful to draw the full-scale form of the knife on paper or cardboard and transfer it to the steel.

- Rough Cutting: The rough shape is cut from the strip or plate. During this process, you must consider the center of gravity of the knife and all proportions, including thickness.

- Visibility Check: Look at your sketch from several angles; does it look asymmetrical? Are there any irregularities in thickness? You can correct these types of errors even with small sandpaper.

Patience is very important at this stage: if you grind a little too much or rush, you can’t “undo” it like in video games!

Grinding and Sharpening

Grinding not only clarifies the shape of the blade; the sharpening stage also begins with grinding. The process proceeds as follows:

- Profile Grinding: You gradually thin the blade from its thickness toward the edges in a line. A conveyor belt grinding machine (belt grinder) is a lifesaver here.

- Intermediate Sanding: The stone can be overly aggressive, so a coarse sandpaper is used first to shape the blade, followed by finer-grit sandpaper to refine the shape.

- Edge Finishing: In the final stage, the edge is refined using more delicate tools such as felt or abrasive bone.

- Sharpening with a Grinding Stone: Japanese stones or hand sharpening sets are used to give the blade a sharp and durable edge.

In these processes, you can balance the sharpening angle and multi-phase grinding (e.g., primero 25° then 15°)—it’s these fine details that give the blade its character.

Handle Design and Assembly

Handle Material Selection

The handle is a vital component in terms of both aesthetics and usability. The handle materials you can choose from are as follows:

- Wood: Natural materials such as olive wood and walnut provide a warm, natural look. However, they are vulnerable to water and impact, so they should be treated with a service oil or epoxy coating.

- G10 and Micarta: Composite, water-resistant, and durable. Ideal for outdoor use.

- Rubber or TPE: Soft texture prevents slipping but wears out faster.

- Bone or Leather: Traditional, aesthetic options.

When choosing a handle, the intended use and the general purpose of the knife should be the deciding factors. For example, G10 or Micarta provide a good balance for camping, while wood is a good choice for aesthetic purposes.

Assembly Techniques

To mount the handle to the knife, follow these steps:

- Prepare the handle pieces (such as a cane handle).

- Secure the full tang with glue.

- Drill holes for pinning, apply epoxy.

- Tighten the pins and smooth the edges with grinding.

- In the final step, fill with putty after epoxy and grinding, then polish and apply a finish if necessary.

This step, if not done correctly, can cause the handle to separate from the blade. Be careful!

Finishing and Surface Treatments

Polishing and Coating

Finishing processes add both aesthetic appeal and protective properties to the blade:

- Brushed Matte Finish: Through polishing stages on steel, you can create matte surfaces that reflect light.

- Bead Blast Coating: Provides a sandblasted, smoky appearance.

- Corrosion-Resistant Coatings: Coatings such as epoxy, bronze, or patina protect against external influences and create atmosphere.

Safety and Handling Tests

Once your knife is complete, final testing is critical not only for appearance but also for safety:

- Handle/Table Stability Test: Does the knife handle wobble?

- Sharpening & Sharpness Test: Check the sharpness level with tests such as cutting paper or tomatoes.

- Hammer Impact Test (Controlled): Test the handle connection and body integrity by applying an impact to the knife.

- Water Exposure Test: Especially for knives with wooden handles, expose them to water for a few hours and check for swelling or deformation.

Safety Precautions and Legal Considerations

Workshop Safety

During manufacturing, always follow these rules for personal safety in the workshop:

- Safety goggles, earplugs, mask.

- Use of gloves: You can safely complete your work with appropriate gloves when working with sharp tools.

- Ensure proper ventilation for flames and smoke.

Legal Limits and Regulations

There are certain legal restrictions regarding the carrying and production of knives in Turkey. Regular sellers may be subject to regulations similar to those governing firearms. It is recommended that you conduct your research using current official sources.

Sheath (Scabbard) Design and Production

H3: The Importance of a Sheath

No matter how sturdy and sharp a camping knife is, if it is not carried in a suitable sheath, it can become dangerous and may be damaged. A sheath protects the knife, facilitates carrying, and enhances user safety. It also adds aesthetic value to the knife.

Like knife production, high-quality sheath production requires attention to detail. The sheath must fit the shape of the knife perfectly, and the knife must not slip when inserted or removed.

Leather, Kydex, and Fabric Options

Three types of sheaths are commonly preferred for camping knives:

- Leather Sheath: A classic and aesthetic choice. Properly processed genuine leather offers both durability and a stylish appearance. However, it is sensitive to moisture.

- Kydex Sheath: A durable plastic material that is shaped by heat. It is waterproof, lightweight, and has a modern appearance.

- Fabric/Nylon Sheath: A more affordable and lightweight option. However, it is less effective at securing the knife.

Details such as stitching techniques, rivets, and clip systems used during sheath production also directly affect durability.

Knife Personalization Techniques

Engraving and Processing Techniques

If you want to add a personal touch to your knife, don’t hesitate to decorate it. Engraving can be done by writing names, symbols, or dates.

- Laser Engraving: Modern, precise, and long-lasting. Widely used in workshops.

- Hand Engraving: A method that requires skill but is very aesthetic.

- Acid Etching: It is possible to engrave patterns on metal surfaces using chemical reactions.

Patterns and Colors on the Handle

The handle is also an area that is very open to personalization. You can make a difference with handles made of colored resins, mosaic pins, or stamped metal pieces. You can also add character to your knife with burn patterns applied to natural wood.

Camp Knife Care and Sharpening Techniques

Proper Storage and Cleaning

Just like knife production, proper care after use also extends the life of a knife. Here are some care recommendations:

- Clean after each use.

- If it is carbon steel, do not leave it damp; it will rust.

- Apply maintenance oil to the handle.

- Do not leave it in its sheath for long periods of time, especially leather sheaths.

Effective Sharpening Techniques

To maintain the sharpness of the knife, it should be sharpened regularly. Points to consider when sharpening:

- Always sharpen at the same angle.

- Use Japanese sharpening stones (grit 1000–6000).

- Oiled stones or ceramic sharpening rods are also good options.

- Rub the knife against the stone evenly without pressing too hard.

With regular maintenance and proper sharpening, your knife will remain as sharp as the first day for years.

Tips for Beginners

Choose a Simple Design for Your First Knife

The biggest mistake beginners make is starting with complex, aesthetically focused projects. Remember, function always comes before form. My recommendations are as follows:

- Start with a full tang and fixed blade design.

- G10 or plywood handles are easier to work with.

- Choose easy-to-work carbon steels such as 1095.

- Focus on hand tools for maximum efficiency with minimal equipment.

Don’t Be Afraid of Mistakes – Learn

Your first knife may have burrs, the handle may be misaligned, or the blade may not be symmetrical. These are all natural. Every mistake is the foundation for your next production. Enjoy the process and be open to learning.

Camping Knife Sales and Branding Process

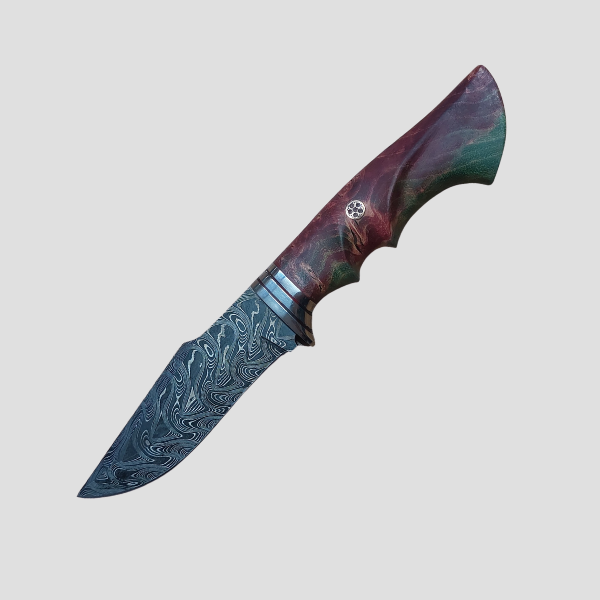

Product Photography and Presentation

Promoting your knife effectively is just as important as making it. If you plan to sell on social media or e-commerce platforms:

- Take high-resolution photos.

- Use natural light and a plain background.

- Include a scale object (such as a matchstick) next to the product.

- Pay attention to your packaging design.

Brand Creation and Online Sales

If you want to turn this into a sustainable income, branding is essential:

- Choose a simple, memorable brand name.

- Design your own logo (laser engraving on the knife is also recommended).

- Showcase your products on a website.

- You can start selling on platforms such as Etsy, Instagram, and Facebook Marketplace.

Mastery at the Tip of the Knife

Camp knife manufacturing is an art that requires patience, attention, and passion. The satisfaction of a knife made by hand is priceless, both in use and in the production process. In this guide, we have walked you through every step of the process, from scratch to professional level. You can now design, produce, and perhaps even sell your own camping knife. Remember, every sharp knife is sharpened by a master’s sweat!

Türkiye’den Dünyaya Kaliteli Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları imal eden firma.

Palta Outdoor, doğaya saygılı ve yeniliğe açık bir ekip tarafından tasarım ve tutkunun birleşimiyle doğdu. 1997’de Denizli’nin Serinhisar İlçesi Yatağan Mahallesi’nde başlayan geleneksel bıçakçılık serüvenimizi, 2020’de modern üretim teknikleriyle buluşturarak Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları ve kamp malzemeleri imalatı alanında dünya çapında bir marka haline geldik.

Türkiye’den Dünyaya Kaliteli Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları imal eden firma.

Palta Outdoor, doğaya saygılı ve yeniliğe açık bir ekip tarafından tasarım ve tutkunun birleşimiyle doğdu. 1997’de Denizli’nin Serinhisar İlçesi Yatağan Mahallesi’nde başlayan geleneksel bıçakçılık serüvenimizi, 2020’de modern üretim teknikleriyle buluşturarak Bıçaklar, Baltalar, Kılıçlar ve Outdoor Ekipmanları ve kamp malzemeleri imalatı alanında dünya çapında bir marka haline geldik.