The knife is one of the oldest and most indispensable tools in human history. From ancient times to the present day, it has been used in every field, from hunting to cooking, from handicrafts to defense. However, what makes a knife truly “a good knife” is not just its sharpness. Knife manufacturing is an art in itself, from selecting the right steel to skillful forging and combining it with a well-balanced handle.

By the end of this article, you will learn in detail how a handmade knife is created, what stages it goes through, and what to pay attention to at each step. Whether you are thinking of making your own knife or are simply curious about how a high-quality knife is produced, the information provided here will be both theoretical and practical.

In addition, you will find answers to the following questions in the following sections:

- How are knives made?

- What are the stages of handmade knife production?

- Which steels are preferred in knife manufacturing and why?

- What is heat treatment and what is it used for?

- How can you tell the quality of a knife?

In this guide, which is based on centuries of expertise, you will not only learn technical information, but also discover the spirit behind knives that are produced with skill and care.

If you are ready, let’s discover together how a real knife is made.

This article may interest you. How to Choose the Right Camping Knife for Your Needs?

1. Introduction to Knife Manufacturing: The Difference Between Handmade and Mass Production

Knife manufacturing may seem simple on the surface, but it actually involves many different production approaches. There are significant differences between handmade knives and mass-produced knives. These differences directly affect both the quality of the product and the user experience.

What is Handmade Knife Manufacturing?

Handmade knives are special products that reflect the knowledge, skill, and craftsmanship of a master craftsman. These types of knives generally involve the following steps:

- Hand-forged steel is used: The consistency and direction of the steel are controlled by the craftsman.

- Each knife is crafted individually: This ensures high quality in the details.

- The balance between the handle and the blade is adjusted by hand: This determines how the knife fits in the hand and how comfortable it is to use.

- Designed for collection or lifelong use: These knives are preferred for specific uses, such as camping knives, butcher knives, or chef’s knives.

How Are Mass-Produced Knives Made?

Mass-produced knives are products that are automatically cut, shaped, and assembled by machines. Generally:

- Rapid production is achieved using molds

- Each product is identical to the next

- Aims for affordable prices and high volume sales

- While quality control standards are in place, there is no personal touch

Differences Between Handmade and Mass-Produced Knives

| Criterion | Handmade Knife | Mass-Produced Knife |

|---|---|---|

| Production Time | Long – labor-intensive | Fast – automated system |

| Material Quality | Specially selected steels | Standardized steels |

| Sharpness | Hand-sharpened | Factory-set |

| Usage Purpose | Professional & personal use | Daily use |

| Price | High but long-lasting | Affordable – short-term solution |

| Aesthetics | Customized – distinctive | General design |

Which Knife Is Right for You?

If you are a professional user—for example, a butcher, someone who camps in nature, or a master of flavor in the kitchen—a product made with handmade knife manufacturing will provide you with comfort, confidence, and long-lasting performance. Because these knives are designed and manufactured by masters who think like you.

On the other hand, if you are looking for a practical and economical option for everyday home use, mass-produced knives can also meet your basic needs.

2. Material Selection: What Type of Steel Is Used in Knife Manufacturing?

The foundation of a good knife lies not only in craftsmanship but also in the right choice of materials. The question of what type of steel is used in knife manufacturing is one of the most frequently asked questions by both manufacturers and users. This is because the type of steel directly determines the sharpness, durability, and maintenance requirements of the knife.

What Types of Steel Are Used in Knives?

1. Carbon Steel (e.g., 1095, 1080, C75):

- One of the most commonly preferred types of steel in handmade knife manufacturing.

- It is very hard and sharp but more susceptible to rust.

- It is often preferred in the production of camping knives and butcher knives.

- It is easy to sharpen but requires regular maintenance.

2. Stainless Steel (e.g., 440C, AUS-8, 12C27):

- It is corrosion resistant and suitable for outdoor use.

- It is preferred for household kitchen knives and outdoor knives.

- It retains its sharpness for a long time but is slightly more difficult to sharpen than carbon steel.

3. Tool Steel (e.g., D2, O1):

- Offers high wear resistance.

- Has semi-stainless properties.

- It is commonly seen in the special productions of master craftsmen who make forged knives.

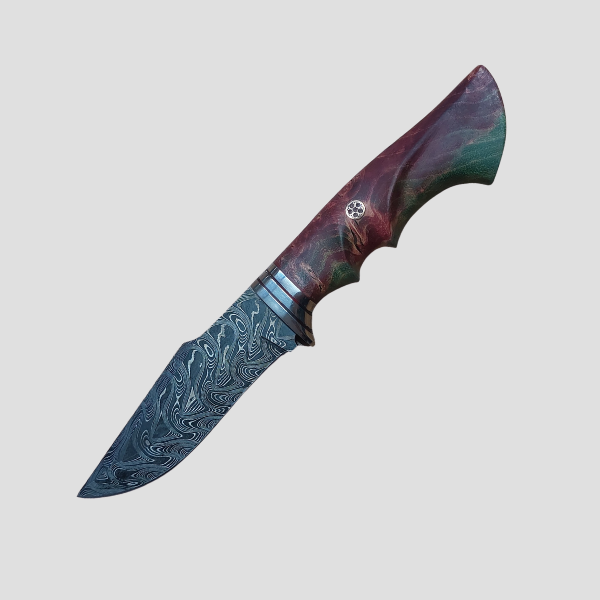

4. Laminated Steel and Multi-Layered (e.g., Damascus):

- Provides both durability and aesthetic appeal.

- Obtained by layering and forging different types of steel.

- Preferred for collectible knives and custom-designed chef’s knives.

How to Choose Steel Based on the Purpose of the Knife?

| Type of Use | Recommended Steel Type | Why is it Preferred? |

|---|---|---|

| Camping Knife | Carbon Steel (1095, C75) | Superior performance in harsh conditions, easy to sharpen |

| Butcher Knife | D2, 440C | Hard, hygienic, and long-lasting |

| Chef’s Knife | 12C27, AUS-8 | Stainless, balanced, precise cutting |

| Collectible | Damascus, O1 | Visual aesthetics + special craftsmanship |

Expert Tip: “Don’t Choose a Knife Without Knowing the Steel!”

Every steel has its advantages as well as its disadvantages.

For example, 1095 carbon steel is excellent in nature but requires regular maintenance (oiling, drying).

440C stainless steel, on the other hand, is easy to maintain but may not achieve the necessary edge hardness for professional butchers.

This is why the handmade knife production process is not just about shaping—it is also the art of selecting the right steel for the specific need.

3. Forging and Shaping: The First Step in Mastery

The character of a knife begins to take shape the moment the first blow is struck on the steel. This stage is not merely a technical process but also a craft that requires mastery, as it reflects the essence of knife making. Especially in the handmade knife production process, forging is the most critical step that directly determines the quality and durability of the knife.

What is Forging?

Forging is the process of shaping steel heated to high temperatures using hammer blows. During this process, the steel’s structure becomes denser, its internal voids close, and its resistance to impacts, bending, and breaking increases. Forging also enhances cutting performance by aligning the steel’s grain structure.

A camping knife made from forged steel provides users with both durability and an aesthetic texture.

Shaping Methods: Traditional or Modern?

Traditional Hand Forging

- Shaping with a hammer on an anvil

- Each knife is unique and bears the craftsman’s mark

- Craftsmanship and art go hand in hand

Modern Techniques

- Shaping with laser cutting and CNC machines

- Suitable for mass production, precise measurements

- Lacks a personal touch; the spirit is determined by machines

The Shape of the Knife: It Cuts as It Is Forged

- Camping knives are generally forged to be thick, durable, and versatile.

- Butcher knives should be long and thin; they must be both sharp and flexible.

- Chef’s knives require balanced weight and a smooth curve—this is achieved with skill during the direct shaping phase.

The Craftsman’s Touch: Infusing Shape with Soul

Every hammer strike is guided by the craftsman’s knowledge and intuition. When to apply heat, when to forge the steel, when to let it cool—these are things felt through years of experience, not by a machine.

That’s why traditional knife making transforms into a work of art that carries the craftsman’s character.

4. Heat Treatment: Giving the Knife Hardness and Character

No matter how skillfully a knife is forged, it can only achieve its true performance with the right heat treatment. This is because steel cannot fully demonstrate its sharpness and durability without its internal structure being altered. That is why heat treatment in the knife manufacturing process is like a ritual that gives steel its character.

What is Heat Treatment?

Heat treatment is the process of heating steel in a controlled manner and then cooling it at a specific rate. This process changes the microstructure of the steel and gives it both hardness and flexibility.

Heat treatment in knives is typically carried out in three main stages:

- Normalization (preheating): To eliminate internal stresses

- Hardening: Heating to a specific temperature and then rapidly cooling with water, oil, or air

- Tempering: Reheating at a lower temperature to establish a balance between hardness and brittleness

What is HRC and Why is it Important?

Blade hardness is typically expressed in HRC (Rockwell Hardness Scale). The higher the value, the longer the cutting edge of the blade will last.

| HRC Value | Property | Application |

|---|---|---|

| 52–56 HRC | Medium hardness, easy to sharpen | Butcher knives, pocket knives |

| 56–60 HRC | Balanced structure | Chef’s knives, camping knives |

| 60+ HRC | High hardness, heavy-duty use | Specially designed forged knives |

Heat Treatment Errors and Effects

- Hardening at the wrong temperature → The internal structure of the blade is damaged

- Insufficient tempering → The blade becomes hard but brittle

- Uneven cooling → The steel cracks, bends, or sparks

Therefore, heat treatment in handmade knives must be performed with master control and experience. Each steel requires different temperatures and times; only a master craftsman with years of experience can apply this knowledge intuitively.

The Role of Heat Treatment in Camping and Butcher Knives

- In the manufacture of camping knives, a structure that is both impact-resistant and retains its sharpness is required. This is achieved through the right combination of hardening and tempering.

- In butcher knives, flexibility is paramount; steels that are not too hard but can be sharpened quickly are preferred, and the heat treatment is adjusted accordingly.

Heat treatment is not just a technical process; it is the stage that makes steel useful, giving it “life.”

Behind every good knife, there is always skillfully applied heat treatment.

5. Sharpening and Edge Profiling Techniques

No matter how high-quality the steel used to make a knife is, if its sharpness is not properly established, it cannot serve its purpose. Therefore, one of the most critical stages of knife manufacturing is edge profiling (edge forming) and sharpening. These processes determine the sharpness, durability, and long-term performance of the knife.

What is Edge Profiling?

Edge profiling is the process of shaping the cutting edge of the steel at a specific angle. This process varies depending on the intended use of the knife:

| Knife Type | Edge Angle | Reason |

|---|---|---|

| Chef’s Knife | 15° – 20° | Provides precise and smooth cutting |

| Butcher’s Knife | 20° – 25° | Offers both sharpness and durability |

| Camping Knife | 25° – 30° | Impact-resistant, versatile use |

In handmade knives, these angles are carefully determined by the craftsman. This is because cutting performance directly depends on this precise angle.

Sharpening Techniques and Tools

Sharpening is the process of restoring the sharpness of the blade’s cutting edge. In handmade knives, sharpening is also a process that preserves the knife’s character.

Traditional Sharpening Tools

- Water stone: Used wet, provides fine workmanship

- Ceramic stone: For precise final touches

- Leather strap (stropping): Achieves a mirror-like sharp edge

Modern Sharpening Tools

- Electric sharpening machines

- Magnetic-guided angle sharpening systems

Expert recommendation:

Handmade knives should be sharpened using traditional methods whenever possible. This extends the life of the knife and restores sharpness without damaging the blade.

Sharpening Frequency and Important Information Based on Use

- Camping knives require more frequent sharpening due to frequent use in outdoor environments.

- Butcher knives should be kept in good shape with a quick surface sharpening at the end of each working day.

- Chef’s knives require regular stropping due to the importance of precision.

Why is sharpening special for handmade knives?

Handmade knives are made with sharper angles and more precise tips than factory-made knives. This makes the sharpening process unique. Careful and controlled sharpening is required to avoid damaging the blade’s edge, which has been hand-crafted by a master craftsman.

In conclusion, blade sharpening is not only a process that makes a knife sharp, but also determines its lifespan.

A skillfully executed sharpening is like giving a knife a new life.

6. Handle Selection and Assembly

A knife must not only be sharp; it must also be comfortable to hold, safe to grip, and provide balance during use. All of these factors are directly related to the handle selection and assembly. In the knife manufacturing process, the handle design and application determine the ergonomics, durability, and aesthetic integrity of the knife.

Handle Materials: From Traditional to Modern

Knife handles vary according to different uses and aesthetic preferences. Here are the most popular materials:

Natural Materials

- Walnut, rosewood, olive wood: Aesthetic, warm, and natural feel

- Bone, horn, antler: Commonly used in traditional knives

- Disadvantages: Sensitive to moisture; requires regular maintenance

Synthetic Materials

- Mikarta: Fabric pressed with resin; very durable and stylish

- G10: Glass fiber-based composite; extremely resistant to impact and moisture

- Rubber, thermoplastic handles: Ideal for non-slip grip, especially in camping and tactical knives

The handle material used in handmade knife manufacturing is selected according to both the intended use and the craftsman’s preferences.

Handle Mounting Techniques

Full Tang Mounting

- The metal blade passes through the handle and is secured with rivets from the outside

- The strongest and most durable method

- Preferred for camping and butcher knives

Half Tang Assembly (Hidden Tang)

- The steel is hidden inside the handle and is not visible from the outside

- It has an elegant appearance

- It is common in traditional chef’s knives and special design models

Master Detail: Balance Adjustment

- In a good knife, the center of gravity should not be at the tip or the handle

- The balance point is adjusted with precise measurements during handle assembly

- This balance ensures that the knife is not tiring to use and improves cutting performance

Handle Aesthetics: The Character of the Knife

The handle is not only functional, but also a detail that reflects the identity of the knife.

- Color-graded woods

- Traditional hand carvings

- Personalized engravings are aesthetic details that distinguish handmade knives from mass-produced ones.

The Craftsman’s Perspective: “The Handle is the Knife’s Hand.”

No matter how sharp a knife is, a poorly designed handle tires the user and creates a sense of insecurity. That’s why the question “how is a knife handle made” is just as important as the choice of steel.

A true master shapes the handle according to the hand of the person holding the knife. Because a knife is just iron if it’s not in the hand.

7. Final Touches: Polishing, Finishing, and Branding

A knife may have been forged, shaped, heat-treated, sharpened, and fitted with a handle… but it is still not complete. Because handcrafted knife making requires care at every stage, and it is the finishing touches that elevate the product from “ordinary” to a masterpiece.

Polishing: Bringing Out the Spirit of Steel

The polishing process removes imperfections from the surface of the steel and provides visual cleanliness. At this stage:

- Sandpaper, microfiber polishers, and polishing pastes are used

- Matte, semi-gloss, or mirror-like finishes can be achieved

- In multi-layered steels such as Damascus, the grain structure is clearly visible

Polishing is not only aesthetic but also provides extra protection against rust.

Finishing: The Aesthetic and Protective Complement to the Handle

The handle requires as much attention as the blade. If wood or natural materials are used, polishing is performed to protect and enhance the surface:

- Natural oils (linseed oil, tung oil) or varnishes are used

- Hand-applied polishing preserves the texture of the handle

- A balanced shine that does not create slipperiness should be preferred

Finishing extends the life of the handle and provides a sense of security to the user through its tactile feel.

Marking: Adding the Craftsman’s Signature to the Knife

The final step in production is engraving the brand logo, signature, or manufacturer’s mark onto the knife. This identifies the craftsman and authenticates the product.

- Laser marking

- Electrochemical engraving

- Stamping (hot stamping) are among the methods used.

In handmade knives, the “master’s mark” serves as a quality certificate. Every master should be able to engrave their name on their work with confidence.

The Importance of the Final Touch in Collectible Knives

In knives made for collection or special orders, these final stages are much more detailed.

- Special packaging

- Sheath production

- Certificate/warranty document These knives, completed with such additional processes, become both functional and artistic products.

Master’s Comment: “The final touch of a good knife is the moment it touches the master’s heart.”

Knife manufacturing is not just about forging and sharpening steel. Every detail is shaped by the master’s intention.

Polishing, finishing, and branding are not the moments when a knife is completed, but when it begins to speak.

8. From Craftsmanship to Brand: The Role of Experience in Traditional Knife Making

Knife making is not just about forging steel, attaching a handle, and sharpening. A real knife embodies the master’s past, manual labor, years of experience, and a craft culture passed down from generation to generation. Traditional knife making, in particular, is much more than a job—it is a way of life.

A Journey That Begins with Craftsmanship

Like many masters, we also started this profession as apprentices at a young age. Hours spent at the anvil, understanding the color and temperature of steel, learning the language of steel forged by hand… These things cannot be found in books; they can only be learned through experience.

The handmade knife production process reflects the master’s wisdom, patience, and character.

A Legacy from Our Ancestors: The Genetic Code of Mastery

Some knife masters inherit this art from their ancestors. Passed down from grandfather to father to son, this tradition is not only a technical but also a cultural transfer.

- Which steel is used for what

- How the handle fits

- Which cut tells what story?

The knife you hold in your hand is not just a cutting tool; it is a bridge connecting the past with the present.

Becoming a Brand with Handmade Products: The Institutionalization of Craftsmanship

Today, even masters who produce knives using traditional methods are creating products that bear their own names and brands.

- Custom-made products

- Limited edition collections made by hand

- Boutique series bearing the master’s signature—all of these are part of the branding evolution of handmade knives.

To become a brand, it is not enough to produce; you must communicate and pass on your craftsmanship.

Experience Brings Trust

A good knife reveals itself at first glance.

- Balance

- Sharpness

- Grip

- Material quality The master’s experience is reflected in all these details. Therefore, the role of experience in knife manufacturing is as vital for building trust with users as it is for ranking on Google.

Master’s Quote: “It is not the hand that knows the knife that sharpens the steel; it is the hand that sharpens the man.”

Every master has their own style, every brand has its own spirit.

Every step we describe in this article—steel selection, forging, heat treatment, sharpening, handle assembly, branding—is not just a production process, but also the embodiment of experience.

Every Knife Bears the Mark of a Master

Knife making is not just a job that can be done with technical knowledge. This process begins with the selection of steel, goes through many stages such as forging, heat treatment, sharpening, and handle assembly, but above all, it carries the touch of mastery and experience.

What makes a knife special is not just its sharpness, but the story behind it, the sweat, and the craftsmanship.

In this article, we will provide you with:

- A comprehensive answer to the question, “How are knives made?”

- A step-by-step guide to the handmade knife production process

- Technical answers to the question, “What kind of steel is used in knife manufacturing?”

- How traditional craftsmanship has been transformed into a brand

If you are someone who appreciates the value of a knife made by hand, you now have a better understanding of the skill behind each step. This knowledge will not only help you choose the right knife but also deepen your respect for this craft.

Because a good knife is born from the hands of a good craftsman. And in every cut, it carries a piece of his soul.