The Heart of the Knife – Beats with Selected Steel

No matter how impressive a knife looks, the most important thing is the steel used to make it. Steel directly affects how sharp and durable a knife is, how much maintenance it needs, and how long it lasts. That’s why both craftsmen and users ask this question:

“What kind of steel is used to make knives?”

Although there are hundreds of different types of steel available on the market today, each has its own advantages and disadvantages. The range spans from carbon steel to stainless steel, and from tool steels to multi-layered steels like Damascus. However, knowing which steel is suitable for which application is the most critical step in selecting or producing the right knife.

In this article, you will find clear and understandable answers to the following questions, which are of great importance for both professional knife manufacturers and informed users:

- What is the best steel for knives?

- What are the most commonly used types of steel in knife manufacturing?

- What are the differences between carbon steel and stainless steel?

- Which type of steel is suitable for which type of knife?

- What do HRC value, toughness, and corrosion resistance mean?

If you are looking for a durable knife for camping, are a chef who makes precise cuts in the kitchen, or are interested in collectible handmade knives, this guide will help you make the right steel choice.

This article may interest you. How Are Knives Made? (Step-by-Step Guide from the Masters)

1. What is knife steel? What is it used for?

The steel used in knife manufacturing is not just a piece of metal; it is the most fundamental building block that determines the functionality, durability, and sharpness of a knife. But what exactly is meant by “knife steel”?

How is knife steel selected?

Technically, steel is made by adding carbon (C) and various alloy elements (chromium, vanadium, molybdenum, manganese, etc.) to iron (Fe). Each variable in this composition gives the steel different properties.

The basic criteria for knife steel are as follows:

- Hardness (HRC): How well the knife retains its sharpness

- Toughness: Ability to withstand impact without breaking

- Corrosion Resistance: Resistance to rusting

- Wear Resistance: Resistance to thinning or loss of sharpness over time

- Machinability: Ease of shaping during production

Each type of steel emphasizes some of these characteristics while compromising others. Therefore, the “best knife steel” actually varies depending on the intended use.

Why is special steel used in knives?

- Camping knives require steel that is hard but also resistant to impact.

- Kitchen knives must retain their sharpness for a long time and be easy to clean.

- Butcher knives require both flexibility and easy sharpening

- Handcrafted collectible knives are made from steel that offers both aesthetic appeal and special workability

For this reason, craftsmen choose different types of steel depending on the intended use of the knife. The same knife shape can take on a completely different character when made from different types of steel.

2. Main Types of Steel Used in Knife Manufacturing

The type of steel used in knife manufacturing determines many characteristics, from the knife’s durability and sharpness to its ease of sharpening and corrosion resistance. Master knife makers select steel based on the knife’s intended use to maximize performance.

Below, we will examine the most commonly used and most reliable types of knife steel, along with their advantages and disadvantages:

A) Carbon Steels

Examples: 1095, C75, 1080

- Advantages:

- High sharpness potential

- Easy to sharpen

- Suitable structure for forging

- Disadvantages

- Susceptible to rust

- Requires regular maintenance in humid environments

Where is it used?

Camp knife manufacturing, butcher knives, hunting knives, traditional handmade models

1095 carbon steel offers reliable performance in nature thanks to its hard structure and can achieve excellent sharpness in skilled hands.

B) Stainless Steels

Examples: 440C, 12C27, AUS-8, AEB-L

- Advantages:

- Corrosion resistant (stainless)

- Suitable for home and professional kitchen use

- Easy to maintain, hygienic

- Disadvantages:

- Sharpening is more difficult than carbon steel

- Some types may be brittle

Where is it used?

Chef knives, kitchen knives, everyday utility knives

440C stainless steel stands out for its durability and hygiene, making it ideal for both home users and professional chefs.

C) Tool Steels

Examples: D2, O1, A2

- Advantages:

- High wear resistance

- Remains sharp for a long time

- Those with a semi-stainless structure (such as D2) can be used outdoors

- Disadvantages:

- High heat treatment sensitivity (incorrect processing reduces performance)

- Difficult to process, requires skilled craftsmanship

Where is it used?

Forged camping knives, outdoor knives, collectible custom designs

D2 steel is preferred for its durability in hunting and outdoor conditions.

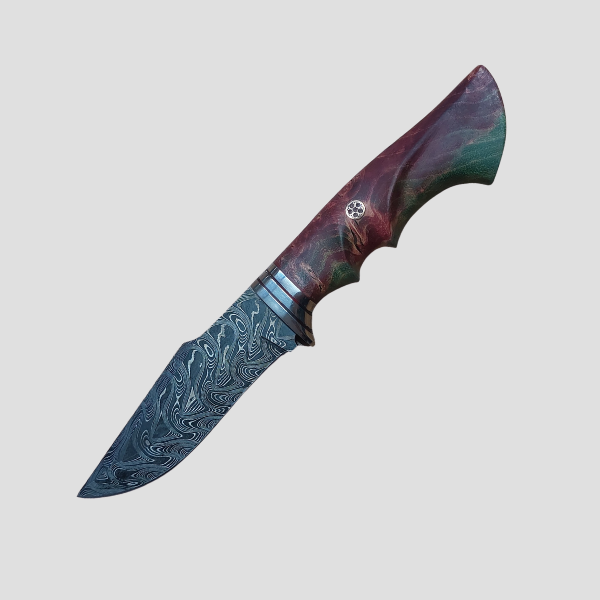

D) Multi-Layered Steels (Damascus / San-Mai)

- Advantages

- Unique aesthetic grain structure

- Layered structure allows for both flexible and hard areas

- High collection value

- Disadvantages

- Difficult and costly to produce

- Not all Damascus steel offers high quality (some are for visual purposes only)

Where is it used?

Collectible knives, chef’s knives, custom-made masterpieces

Authentic Damascus steel is a symbol of craftsmanship, both for its striking appearance and its technical construction.

3. Steel Selection: Which Steel is Suitable for Which Use?

Not all knives are created equal. The needs of a camper, butcher, chef, or collector are different. Therefore, the answer to the question “Which steel is used in knife manufacturing?” varies depending on the application. The table and explanations below will guide you in selecting the right steel.

Steel Selection for Camping Knives

- Recommended Steels: 1095, D2, O1

- Why? Camping knives are subject to heavy use in nature. Therefore, they must be both hard and impact resistant.

- Extra: Carbon steels are easy to sharpen in nature but require maintenance.

Recommendation: A handmade forged camping knife made of D2 steel is a durable and strong choice for nature lovers.

Steel Selectionfor Butcher Knives

- Recommended Steels: 440C, AEB-L, 12C27

- Why? Cutting is a frequently repeated process, so hygiene and easy sharpening are important.

- Extra: Hard yet flexible steels are preferred.

Note: Stainless steels like 440C offer significant advantages for long-term use in butcher environments.

Chef and Kitchen KnivesSteel Selection

- Recommended Steels: VG10, 12C27, AUS-8

- Why? Precision cuts, long-lasting sharpness, and aesthetics are prioritized.

- Extra: Corrosion-resistant steels suitable for fine edge opening are ideal.

Expert Advice: A Japanese-style chef’s knife made from VG10 steel offers both performance and aesthetics.

Steel Selection for Pocket Knives and Hunting Knives

- Recommended Steels: O1, CPM-S30V, N690

- Why? Lightweight, durable, and long-lasting sharpness

- Extra: Steels offering medium to high corrosion resistance should be preferred

For Collectible and Specially Designed Knives For

- Recommended Steels: Damascus, San-Mai, specially forged steels

- Why? Visual quality, craftsmanship, and prestige are paramount

- Extra: Steel is chosen not only for its performance, but also for its story and aesthetic structure

Note: Damascus steel knives are both collectible and functional when produced for practical use.

In Summary:

| Application | Recommended Steel Type | Key Features |

|---|---|---|

| Camping Knife | 1095, D2 | Durability + Easy sharpening |

| Butcher’s Knife | 440C, AEB-L | Hygiene + Long lifespan |

| Chef’s Knife | VG10, AUS-8 | Precision cutting + Rust resistance |

| Folding Knife / Hunting Knife | O1, N690 | Lightweight + Portability |

| Collectible | Damascus, San-Mai | Aesthetic + Craftsmanship |

4. Steel Properties: HRC, Toughness, Corrosion Resistance

To understand how good a steel is, you need to look at its technical properties, not its brand name. The types of steel used in knife manufacturing should be evaluated not only by their type names, but also by their physical and chemical values.

Here are the three most critical properties in steel selection:

1. HRC – Hardness Value (Rockwell Hardness)

HRC is the Rockwell hardness scale that measures how resistant a steel is to pressure applied to its surface. This value is directly related to how long the knife will maintain its sharpness.

| HRC Range | Hardness Level | Application |

|---|---|---|

| 50–54 | Low | Flexible but dulls quickly – pocket knives, general use |

| 55–58 | Medium | Balanced – butcher knives, camping knives |

| 59–62 | High | Long-lasting sharpness – chef’s knives, collectible |

⚠️ Steels with very high HRC (62+) are harder but may be more brittle when subjected to impact. Therefore, “high hardness = best” is not always true; it must be balanced according to the intended use.

2. Toughness – Impact Resistance

Toughness is the ability of steel to absorb impact without breaking. This is particularly important for camping knives and outdoor use. Hard but brittle steel is not reliable in nature.

Example: D2 steel has a high HRC but moderate toughness. O1 steel, on the other hand, is softer but tougher.

3. Corrosion Resistance

Corrosion resistance indicates how resistant steel is to rust when exposed to external factors such as moisture, water, and acid.

- Stainless steels (440C, 12C27, AUS-8) are superior in this regard

- Carbon steels (1095, C75) oxidize quickly and require regular lubrication

- Tool steels (D2) are semi-stainless

High corrosion resistance is particularly important for kitchen and butcher knives. For camping knives, this feature may be secondary depending on the intended use.

Why is it important to balance these three properties?

Steel should ideally be hard, tough, and corrosion-resistant. However, no steel offers all three properties at the same time at an ideal level. Every manufacturer and craftsman selects the appropriate balance between these properties based on the intended use.

The type of steel used in knife manufacturing should not be the “hardest,” but the “most suitable” for the intended purpose.

5. Forged Steel vs. Stainless Steel: Which is Better?

When buying or manufacturing knives, the two most common types of steel are forged steel and stainless steel. So which one is better? Actually, there is no single answer to this question. This is because both types of steel have their own advantages and disadvantages. The right choice is the one that best suits your intended use.

What is Forged Steel?

Forged steel is a type of steel formed by skillfully shaping steel heated to high temperatures using a hammer and anvil. It is the most common method used in handmade knife production.

Advantages:

- High balance of hardness and toughness

- Handcrafted grain structure → longer-lasting sharpness

- Each knife is unique (customization, handcrafted)

- Traditional and robust aesthetic appearance

Disadvantages:

- Typically made from carbon steel → risk of rusting

- Requires more maintenance and care

- Production takes time → higher price

What is Stainless Steel?

Stainless steel is a type of steel containing at least 13% chromium, which makes it resistant to corrosion. It is commonly used in mass-produced kitchen knives.

Advantages:

- High resistance to corrosion and stains

- Requires minimal maintenance

- Ideal for both home and professional kitchen use

- Elegant and clean appearance

Disadvantages:

- Due to its manufactured fiber structure, it may have a shorter lifespan compared to forged steel

- Some types are difficult to sharpen (especially low-quality stainless steels)

- As hardness increases, the risk of brittleness may arise

Comparison Table:

| Feature | Forged Steel | Stainless Steel |

|---|---|---|

| Sharpness Potential | Very high | High |

| Corrosion Resistance | Low (requires regular oiling) | High (easy maintenance) |

| Aesthetics | Unique appearance due to handcrafted work | Smooth, clean surface |

| Durability (Impact Resistance) | High | Medium – High (varies by type) |

| Sharpening Ease | Easy (in carbon steels) | Medium (varies by hardness) |

| Production Method | Traditional – handmade | Industrial – machine production |

Conclusion: Which One Should You Choose in Which Situation?

- In natural conditions, camping, and hunting:→ Choose forged steel (1095, O1). Performance and strength should be prioritized.

- For kitchen and butcher knives where hygiene and ease of maintenance are required:→ Stainless steel (440C, AUS-8, 12C27) is more suitable.

- If you are looking for a collectible or custom-made product:→ Choose forged steel or layered handmade steels like Damascus.

Remember: The best steel is the one that best suits your specific use.

Every steel, when shaped by skilled hands and used in the right place, delivers excellent results.

6. The Importance of Steel Selection in Handmade Knives

A handmade knife is much more than a mass-produced knife. Because a knife made by hand is not just a functional tool; it is also a product of craftsmanship, character, and artistry. And at the heart of this product lies the right choice of steel.

Steel Selection Through the Eyes of a Master

Every master speaks with steel.

- They feel the texture of the steel in their hands

- They know how it behaves at different temperatures

- They can even discern its form from the sound it makes during forging

For this reason, steel selection in handmade knife production is not merely a technical process; it is an art based on experience.

For example, 1095 carbon steel is an excellent choice for a camping knife for someone who spends time in nature. However, the same steel may require excessive maintenance in a kitchen knife and may not be the right choice. This is the difference that masters intuitively understand.

The Right Combination for Balanced Performance

In handmade knives, the steel must be compatible with the design and intended use.

This three-way balance:

- Choosing the right steel for the application

- Achieving the ideal hardness through heat treatment and tempering

- Performance through balanced handle-material compatibility

The goal is not only aesthetics, but also long-lasting use.

Steels Identified with Brand Identity

Some knife masters and brands are identified with specific types of steel.

- “This master craftsman works D2 steel exceptionally well.”

- “This brand creates stunning collectibles using Damascus steel.”

The choice of steel reflects the craftsman’s style and the brand’s identity. This is the key to differentiation in handmade products.

Conclusion: Steel is the Craftsman’s Signature in a Handmade Knife

What makes a knife special is not just how it looks, but how it is made.

Behind a handmade knife:

- Knowledge of the right steel

- Intuition based on experience

- Attention to detail

- And most importantly, respect for craftsmanship

That’s why steel selection is one of the most critical and respected steps in handmade knife production.

Because good steel is a good start—but it’s the master’s hands that make it perfect.

The Best Knife Starts with the Right Steel

Making a knife is much more than heating, forging, and sharpening steel. A real knife starts with the right steel, is shaped by skilled craftsmanship, and becomes a tool you can trust for years to come.

In this guide, we will provide you with detailed information on:

- What types of steel are used in knife manufacturing,

- The differences between carbon steel and stainless steel,

- Steel properties such as HRC, toughness, and corrosion resistance,

- Which steel is more suitable for which application,

- And Why steel selection is so important in handmade knives.

Today, a knife is no longer just a cutting tool; it is a symbol of safety in nature, skill in the kitchen, respect in a collection, and a connection to the past. And at the heart of all this lies the steel that forms the blade.

Whether it’s for survival in nature, creating flavor in the kitchen, or simply as a work of art to display on your shelf…

When the right steel, the right craftsman, and the right craftsmanship come together, the knife that emerges is not just a tool; it is a legacy.